Using an infrared thermometer

The 30hp marinized Kubota engine on our 1979 Dufour 35 had always run a bit hot. The previous owner told us it was happiest at 190°F and 1800 RPM, even though the manual specified an operating temperature of 170°F and 2400 cruising RPM. We didn’t know any better, so we shrugged and bought the boat. A month later the engine temperature was over 200°F.

Finally after two years, thousands of dollars and hundreds of man hours, I discovered the problem. The fix cost $20 and took 5 minutes. The search for the cause of the problem took me through every conceivable system. In many ways it was a boon, as I found a different problem everywhere I looked but not the one causing the excessive engine heat. Not until the very end.

What follows below is my account of the search. I have provided information that I found difficult to find in manuals, talking to mechanics or online. I tried to be systematic in both my approach and in the telling in the hope that readers can take the information and apply it directly to their engines and avoid some of the pitfalls into which I fell. At the bottom of the post I’ve included a checklist for systematically troubleshooting an overheating engine.

This article was originally published in Good Old Boat Magazine in July/August 2017.

RAW WATER SYSTEM

The most common cause of engine overheating is a lack of raw water flow. The first step is to determine how much water is coming out of the exhaust outlet. If I had had more foresight I would have established a baseline flow rate prior to encountering any engine difficulties. Flow rate can be roughly measured through visually inspection, or more exactly by the process outlined below. We did not have such a baseline, so I had to check each component of the system to ensure that there were no constrictions or other issues.

How to determine raw water flow rate

Take a 1 gallon bucket and hold it under the exhaust outlet at a set RPM (2000 RPM works well for most engines). It is easier to do at the dock with the engine in neutral. Time how long it takes to fill the bucket. To determine GPH, divide 3600 by the number of seconds it took to fill the bucket.

Compare this number to your pump rating to determine efficiency of this system, keeping in mind that the flow rate will be less than the specified pump rate due to losses caused by the bends in the hoses. This baseline can also be used as a basis for comparison at a later date.

Note: If it is not possible to catch water from the exhaust outlet, it may be possible to disconnect the raw water intake and connect it to a hose that goes into a 5-gallon bucket. Divide the time it took (in seconds) to drain the bucket into 18 000 to derive GPH.

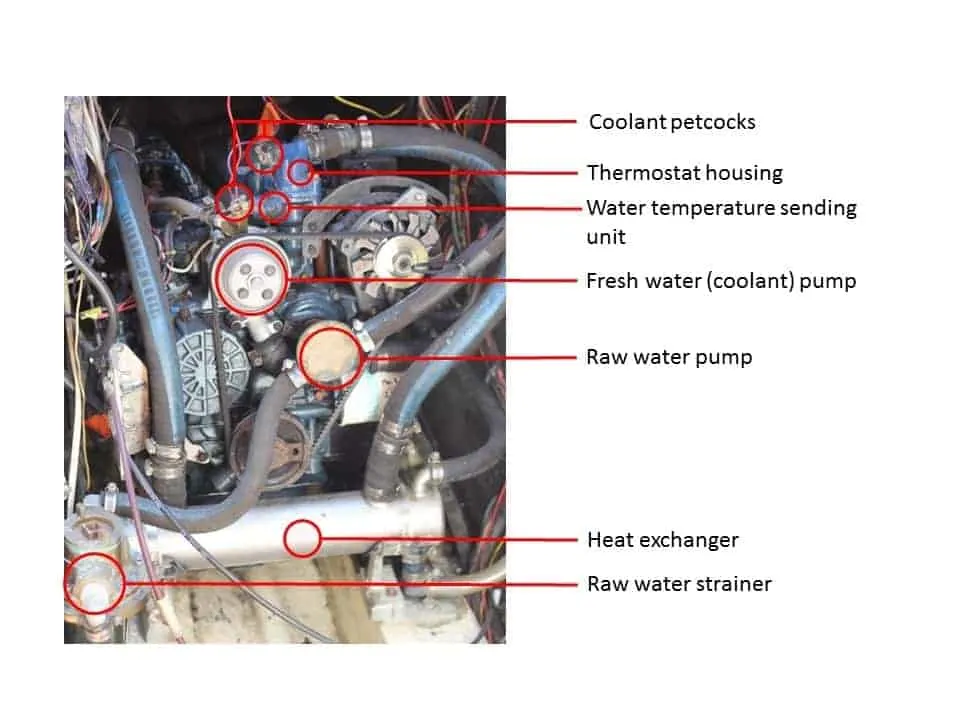

There are many components to the raw water loop, including; thru-hull inlet, strainer, pump and impeller, heat exchanger, and exhaust mixer. I checked each of these components in turn, starting with the thru-hull inlet and working my way to the exhaust mixer.

Raw water strainer

The thru-hull had been recently replaced and there was no visible growth restricting the water flow. I detached the inlet hose from the strainer and opened the thru-hull and water poured in, which was a good sign. Next I checked the strainer for obstruction.

Moving on from there I examined the weep holes on the Jabsco water pump and then took the faceplate off to inspect the impeller. It is a good idea to remove the impeller from the pump housing and examine the fins for cracks, bending each one in turn. If there is any deformation, cracking or other visible anomaly, the impeller should be immediately replaced. If a fin has broken off, it will have been sucked into the rest of the system and should be located. Likely, it will have been trapped in the heat exchanger.

After the pump, I checked the heat exchanger. Calcification had begun to narrow the diameter of the exchanger tubes. I took it to a radiator shop and for $50 USD they submerged it in an acid bath until it was clean. Last in the raw water system, I removed the exhaust mixer, which can be a common cause of flow restriction, and examined it for carbonization, rust or any other blockage. I blew out some black dust, but otherwise the exhaust mixer was clean.

Heat exchanger (silver cylinder)

After putting the raw water system back together, the flow rate was slightly improved, but we still had the same elevated engine temperature. Perhaps the coolant isn’t flowing efficiently I thought, so that became the next target.

COOLANT LOOP

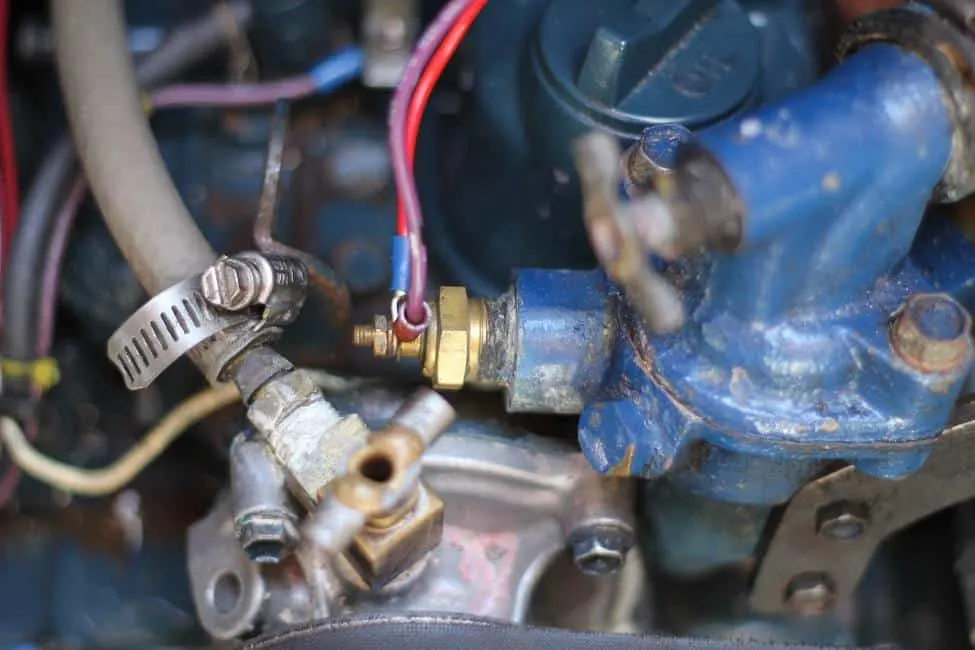

The coolant loop is similarly comprised of various elements, namely; the coolant reservoir, thermostat, heat exchanger, and the fresh water (coolant) pump. It is also a good idea to check the coolant ratio and coolant temperature sender unit. Upon further examination of the coolant loop I found a number of small issues.

The level of coolant in the coolant reservoir was normal and there were no airlocks as I discovered by opening the petcocks at the pump and thermostat. Opening a petcock with the engine running at operating temperature will give you an idea of the coolant flow rate. Coolant gets quite hot so remember to wear protective clothing and equipment. Let the coolant run into a cup. You can set a baseline similar to the one for the raw water flow rate.

Due to the risk of freezing in the Pacific Northwest, we had a 50:50 coolant ratio of ethylene glycol to water. Thinking that the warmer summer water might be part of the problem, I changed the ratio to 30:70 ethylene glycol to water, which is the recommended minimum ethylene glycol content of engine coolant. The specific heat capacity (ability to absorb heat) of ethylene glycol is less than water, so more water equals more heat absorption. If you don’t know the coolant ratio you can use a device that measures specific gravity of the coolant, similar to a battery tester, and which can be bought for under $20 USD at most automotive stores.

- Fresh water pump

- Thermostat

While the coolant was out of the system, I removed the thermostat and checked that it was functioning correctly by placing it in a pot of heating water and noting its action at specific temperatures. This was fairly easily done with a pot on the stove and a thermometer. I should have checked the sender unit at this time as well, but, foolishly, I didn’t. The heat exchanger was previously removed (see above) due to calcification and at the time I examined the coolant portion of it for any sign of damage or blockage.

Lastly, I checked the fresh water pump, which had visible discoloration around the weep hole, indicating a failed mechanical seal. I disassembled the pump and found the shaft to be scored from the failed seal, which necessitated a replacement pump.

After putting the coolant system back together and adding the new ratio of coolant we found that the engine temperature was still over 200°F at cruising RPM. Assured that the raw water and coolant systems were functioning properly, the next step was to make sure the engine wasn’t overloaded.

ENGINE OVERLOAD

Common causes of engine overload are: a fouled propeller, rough hull surface, auxiliary equipment, adverse conditions, or an oversized propeller.

The boat had been out of the water recently and the hull sanded and painted and the propeller wasn’t fouled. We have very little auxiliary equipment, but turned it all off, just to make sure that it wasn’t contributing to the problem. Even with all equipment off, the temperature was unaffected. The high temperature would occur even in a flat calm sea so adverse conditions weren’t to blame.

We checked the propeller size using an online propeller calculator and discovered our propeller was twice the recommended size; no wonder we could reach hull speed well below cruising RPM. After much research we purchased and installed a used propeller of the correct diameter and pitch. The difference was immediate and dropped the temperature down to under 200°F at cruising RPM, but not to the 175°F that it should have been according to the engine manual and thermostat.

If the engine was no longer overloaded, perhaps it wasn’t running efficiently. Things like cylinder misfire, worn piston rings, faulty injectors or malfunctioning valves can cause all sorts of problems, overheating being one of them.

VALVES, INJECTORS, CYLINDERS

Cylinder misfiring can be irregular or rhythmic. In the case of rhythmic misfire, the easiest check of the injectors and cylinders is to loosen the nut that holds the injector to the engine while the engine is running until fuel seeps out. If the engine vibration and/or pitch changes, than the injector is working and the cylinder is firing. If not, then there is a problem with that injector/cylinder.

- Fuel injectors

- Rocker cover

- Oil cap unscrewed

Another thing to check is the crankcase breather tube. If the piston rings are worn, it can cause excessive blow-by and increase the pressure in the crankcase. Place a cup or water bottle cut in half under the breather tube to catch any oil that splurks out. It is normal to have a very small amount of oil, but if it is more than that it could indicate a problem with the piston rings. Also, while the engine is running at idle loosen the oil fill cap all the way, but don’t remove it. It should bounce around in its hole but not get blown off. If it won’t stay in the hole, it may also indicate piston ring wear.

Our cylinders were all working well, so we moved onto the valves. The valves are checked using feeler gauges and have a very small operational tolerance (thousandths of an inch). We respaced all the valves finding that two of them were out of tolerance by a large margin. We also examined the valve seats and they looked clean and undamaged. While spacing the valves may have improved the engine’s efficiency, it unfortunately did not solve the overheating issue.

TEMPERATURE GAUGE AND SENDING UNIT

The thing we did last was the thing we should have done first; check if there was actually a problem at all. Most of us rely on a temperature gauge and a sender unit to tell us the water temperature (coolant) of the engine. We were assured by professionals time and time again that sender units and gauges almost never fail. The operative word proved to be ‘almost’.

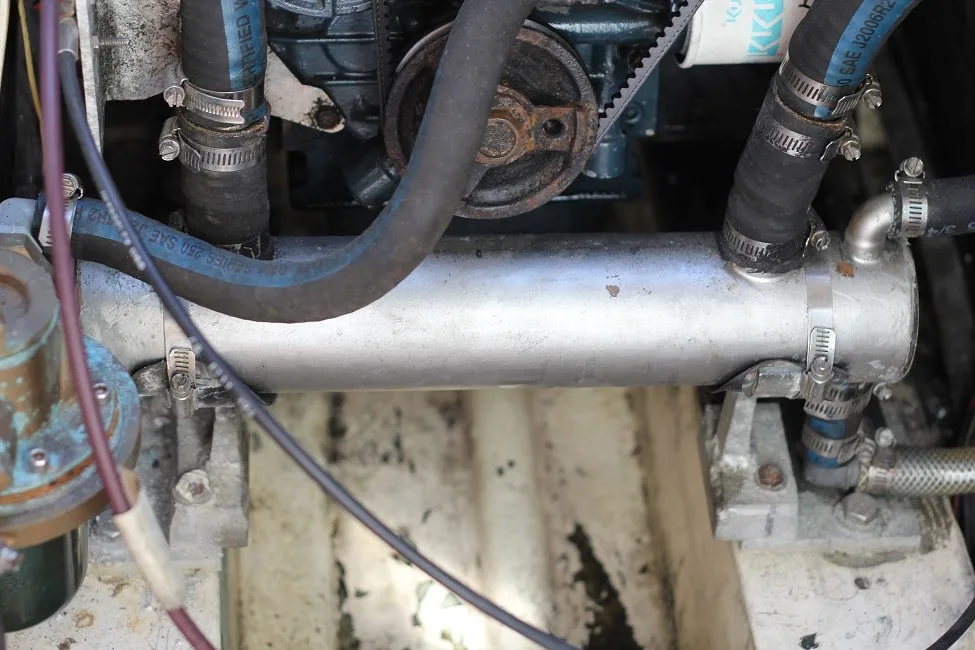

The easiest way to check the engine’s temperature aside of the sender and gauge is to use an infrared (IR) thermometer, also known as a temperature gun. It uses a laser beam to measure the amount of heat energy that a surface emits. The beam widens as it gets farther from the ‘barrel’ of the temperature gun; different guns have different ranges. I hold the thermometer six inches from whatever I am measuring to isolate that particular element. The measurement is most accurate on dark surfaces as the beam won’t be reflected. Shiny surfaces can be colored with a black marker or engine paint to improve readings.

I first measured the thermostat housing and was surprised to see that it registered only 175°F on the IR thermometer, while the engine temperature gauge read 195°F. Considering the IR thermometer at fault, I calibrated it on a boiling pot of water, my partner’s tongue, the refrigerator and a book at ambient temperature. It checked out fine. So I aimed it at the heat exchanger inlet and outlet. There should be a 10-20°F drop in temperature across the heat exchanger as heat is removed by the raw water. There was a temperature drop, but it dropped from 170°F to 155°F. Then I took the temperature of the sender unit, it too was 175°F and I felt my heart hit the floor. There was no overheating problem. Sickened and elated I set about determining whether it was the sender or the gauge at fault.

- Using an infrared thermometer

- Temperature sender unit

Sender units are devices called thermistors. An electrical current is sent through them and their resistance to the current changes proportionally with the temperature. Sender units have known resistances at certain temperatures, so it is a matter of getting the sender unit to temperature and then measuring the resistance with a multi-meter by touching the multi-meter leads to the base and the contact of the sender. The resistance of our sender unit did not match its specifications, verifying that it was indeed malfunctioning.

PROBLEM SOLVED

I replaced the temperature sender unit and the temperature gauge just to be sure. Our first foray out of the harbor had the engine running at 175°F at cruising RPM. But it seemed to take a long time to get up to temperature. It’s not good for a diesel to run at cool temperatures and now our engine seemed to be running too cold. Hmmmm…maybe I should look into it.

OVERHEATING ENGINE TROUBLESHOOTING CHECKLIST

- INITIAL CHECKS

- Check raw water flow rate

- Check coolant level and for coolant leaks

- Check oil pressure and oil level

- Check temperature of engine with an infrared thermometer

- SYSTEMATIC CHECKS

- Raw water system

- Check thru-hull for obstruction

- Check strainer for obstruction

- Check raw water pump weep holes

- Check water pump impeller

- Check heat exchanger for obstruction or calcification

- Check exhaust mixer

- Coolant loop

- Check coolant resevoir/level

- Open coolant petcock while engine is running

- Check for airlock

- Check flow rate

- Check coolant ratio

- Check thermostat

- Check sender unit/temperature gauge

- Check fresh water pump weep holes

- Engine overload

- Check for fouled propeller

- Check for extremely rough/fouled hull surface

- Check for auxiliary equipment power draw

- Check for oversized propeller

- Valves, injectors, cylinders

- Loosen and tighten the injector nut for each cylinder in turn and check for pitch/vibration change

- Check crankcase breather tube

- Loosen oil fill cap and check for blowby

- Check valve spacing

- Raw water system

Robin was born and raised in the Canadian North. His first memory of travel on water was by dogsled across a frozen lake. After studying environmental science and engineering he moved to Vancouver aboard a 35’ sailboat with his partner, Fiona, with the idea to fix up the boat and sail around the world. He has written for several sailing publications including SAIL, Cruising World, and was previously a contributing editor at Good Old Boat.