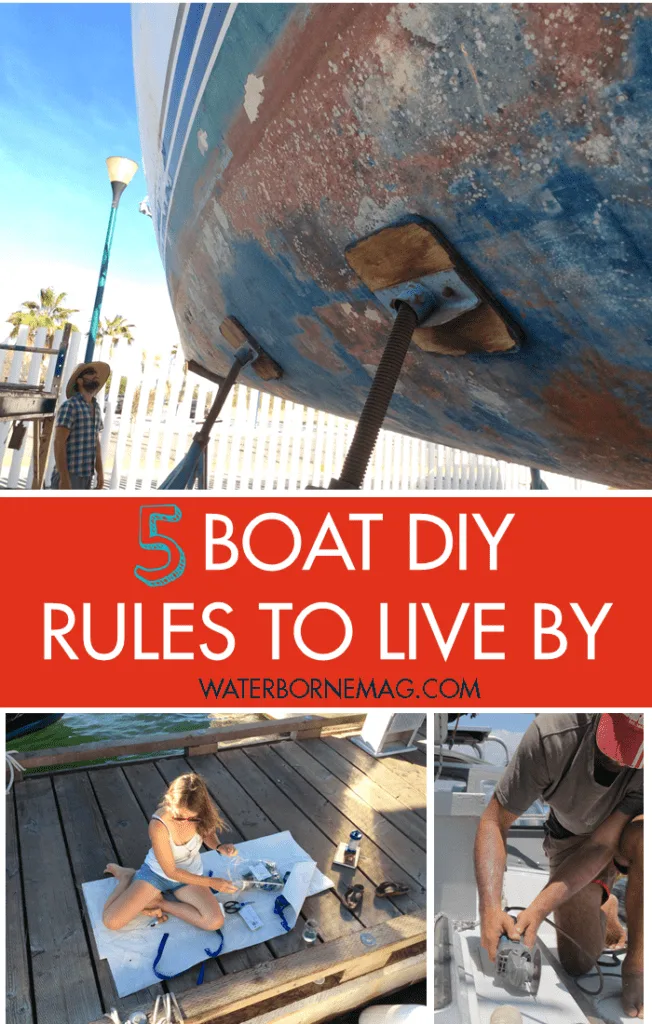

Each spring and fall we embark on our boat DIY projects, brimming with enthusiasm (how hard could it be to rebed a couple of leaky hatches?) only to find ourselves an hour or so later utterly defeated and weeping into a puddle of semi-cured Sikaflex.

We’ve been thinking about how best to avoid our perennial DIY dramas and put some of our hard-won lessons to good use.

Here are our 7 tenets for staying sane in the boatyard along with our DIY confessional (we’ve broken every rule on the list!).

1. Know thy project

Search the web, call product manufacturers, and query other cruisers before starting.

The more time and effort you put into planning and understanding your project the less time and hassle it will be once you start.

We’ve spent many hours cursing a project only to discover that some kind soul has posted a step-by-step how-to on YouTube–if only we’d had that in the beginning!

2. Prep thy tools and work area

Lay out all of your tools in one place before you start. Take time to prep your work area with tarps, cardboard, and tape.

One of our biggest blunders was failing to adequately protect our newly installed hatches before moving onto our next project: fiberglass deck repairs.

The next day we noticed cured fiberglass drips on our beautiful new glass and there was nothing to be done about it.

3. Measure twice, and cut once

It’s an old builder’s axiom, but it holds true for boats. I once misread our calipers while ordering a part. It took a week to receive the wrong part and then another two weeks for them to ship us the correct replacement.

4. Dry fit, dry fit, dry fit.

Dryfitting takes extra time and often gets omitted in the excitement of beginning a project.

Our most shining example: deciding to forgo a dry fit while rebedding the pulpit. We were in a rush because the sun was going down and it was time for beers.

Out came the Sikaflex and halfway through we discovered that some of the deck bolts were different sizes and that we’d mixed them up. We then spent 2 hours, head lamps on, trying to sort through the sticky mess of bolts.

5. Though shalt always do a test patch

It’s tempting to assume a product will work on the first attempt; after all, it looks so easy in the instruction manual!

Our most recent project came to a sorry end when after stripping and varnishing several sole panels we discovered that we’d scorched the boards with the heat gun.

If we’d done a test patch and practiced with the gun we could have avoided the whole ordeal.

6. Use thy mind not (just) thy muscles

In the heat of the moment it sure is tempting to force something to fit (Robin calls me “the brute” because I’m constantly breaking this tenet, along with numerous fragile parts on the boat.

Take a breath, think through it, get another opinion, and try again without forcing it.

7. Know when to quit

When everything falls apart it’s time to step back and take a breather. Don’t keep hammering away at a project if you’re frustrated. You’ll likely create more work for yourself in the end.

We hope you’ve gleaned something from these humble tenets that they’ll prove helpful in your boat projects this season.

May your epoxy always cure, your paint never peel, and your sense of humor prevail even in your darkest DIY hour.

Fiona McGlynn is an award-winning boating writer who created Waterborne as a place to learn about living aboard and traveling the world by sailboat. She has written for boating magazines including BoatUS, SAIL, Cruising World, and Good Old Boat. She’s also a contributing editor at Good Old Boat and BoatUS Magazine. In 2017, Fiona and her husband completed a 3-year, 13,000-mile voyage from Vancouver to Mexico to Australia on their 35-foot sailboat.